Development History

Business Expansion

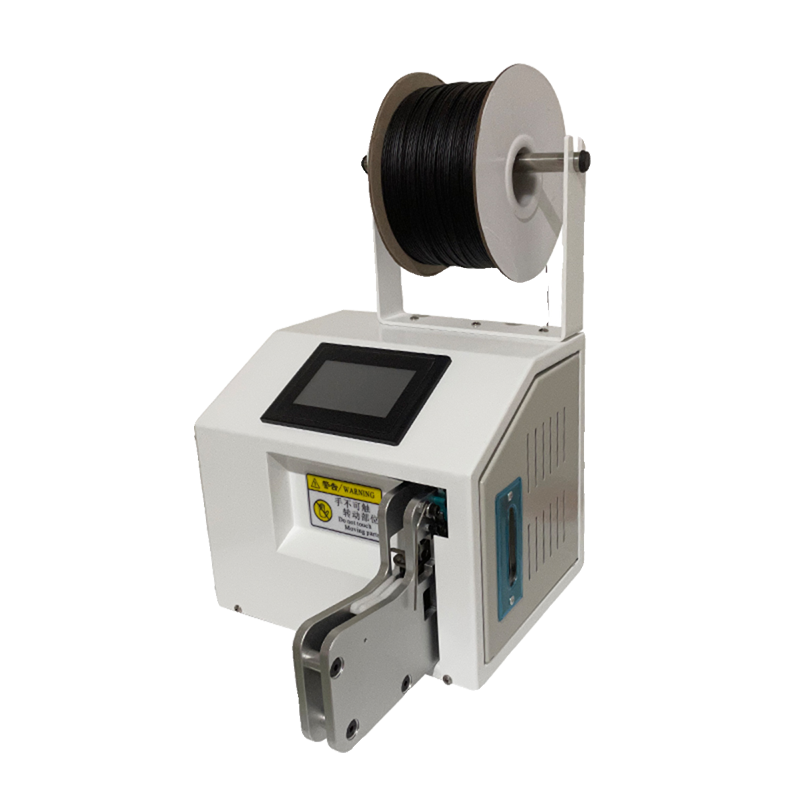

In overseas markets, we increased marketing efforts and participated in internationally renowned industry exhibitions to enhance brand awareness. Subsequently, we developed fully automatic wire winding and binding machines that can be set to 5-100 speed levels and adjusted according to operator proficiency, which are widely popular.

Business Layout

We established a stable supply chain system, controlled product quality, sold high-end products, and developed multi-functional cable stripping machines specifically for processing thick wires, which are particularly popular in automotive, power and other industries.

Achievements and Progress

We recruited professional talents in electronics, mechanical engineering, e-commerce operations, and technology R&D, developed servo terminal machines equipped with open six-sided molds, replaceable M-type/four-point molds, and gradually successfully entered multiple overseas markets with carefully selected materials and processes, gaining recognition from many overseas customers.

Founding Opportunity

In the current global wave, the market's demand for product diversification, intelligence, and cross-border circulation is growing. The founding team, with rich industry experience, keenly captured the combination of traditional manufacturing and emerging fields to fill market gaps.

Sustainability

Sustainability Mission

Use of "100% recyclable packaging", reducing production carbon emissions by 40%.

Partnered with global environmental organizations to launch the "Zero Waste 3D" initiative, empowering green manufacturing.

Global Presence

Headquarters & R&D Center: Henan, China, with a 5,000㎡ smart manufacturing base.

"Market Reach": Products sold in 60+ countries, serving over 100,000 users, covering academic institutions, enterprises, and maker communities worldwide.

Future Vision

Develop "bio-based degradable materials" to reduce reliance on petroleum-based plastics.

Build a "distributed manufacturing network", connecting global users and factories through an AI cloud platform for "on-demand production, zero-inventory delivery."